About FSSC22000 and FSMA

-To be the world's safest and most consistent Crispy tempura bits production factory-

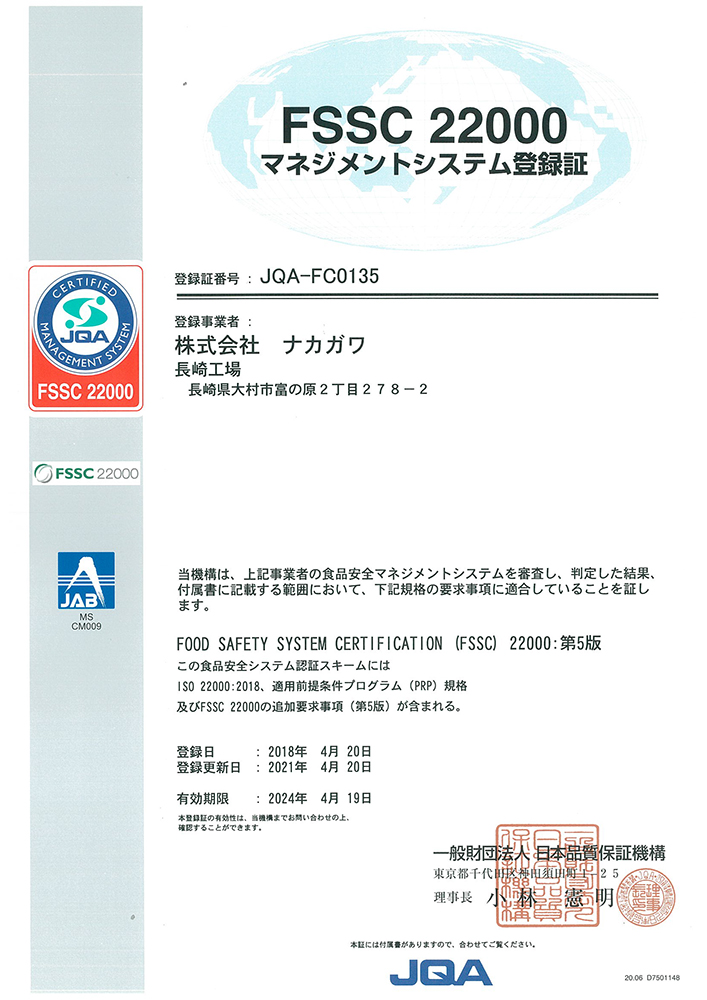

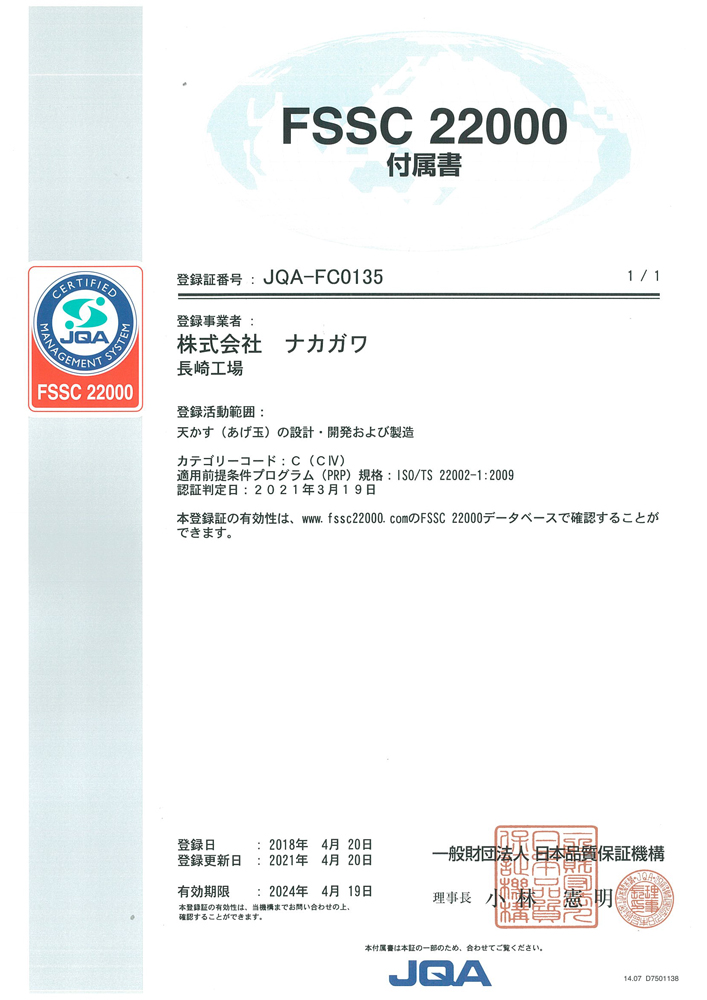

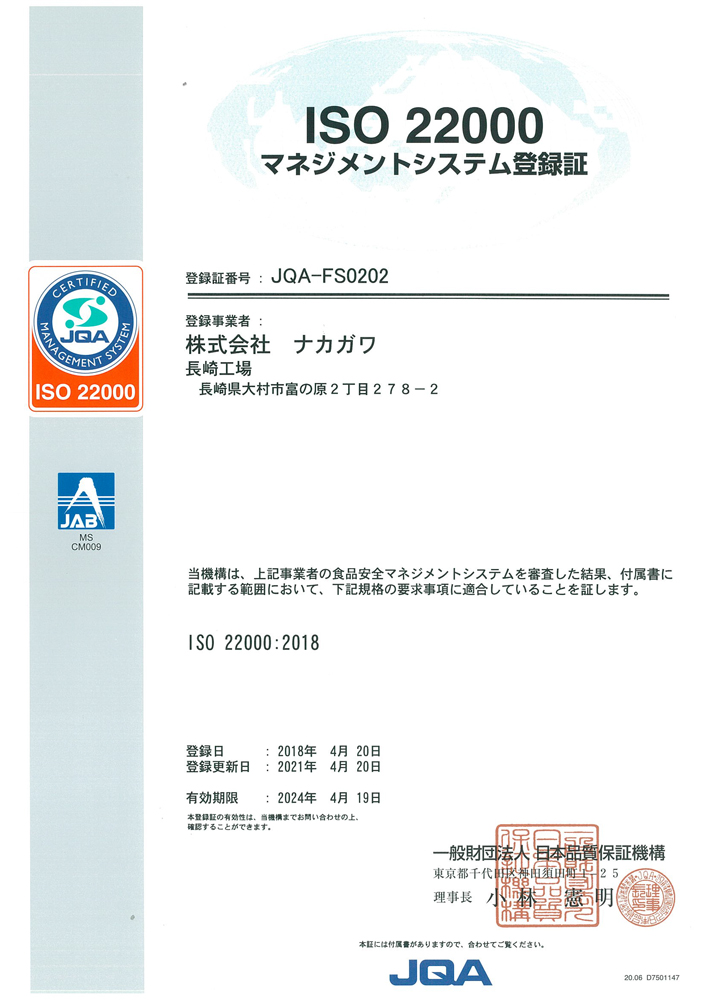

FSSC22000 Certification

We have always carried out efforts to move ahead of our competition for best-in-class safety and consistency of our Crispy tempura bits.

The establishment of our Quality Control Group in the year 2000 at the Nakagawa Nagasaki Plant and the acquisition of ISO 9001-HACCP certification in 2004 were both acquired on first attempts.

In April of 2018, the Nakagawa Nagasaki Plant became the first Crispy tempura bits production facility in the world to acquire FSSC 22000 GFSI approval, the world's top-class food safety standard.

What is FSSC22000?

FSSC 22000 is an international standard of the world's top food safety system integrating "ISO 22000", an international food safety system built on HACCP, and the prerequisite program ISO / TS 22002-1.

It is adopted as a guideline for supply chain management in the world's retail and food manufacturing industry, and adoption of the certification is accelerating even in Japan.

What is the GFSI?

GFSI (Global Food Safety Initiative) is a food safety system established by CGF (The Consumer's Goods · Forum) consisting of global retailers and food manufacturing companies. It is the world's largest trade association aiming for continuous improvement.

What is a GFSI Recognized Scheme?

GFSI evaluates food safety systems around the world based on the GFSI guidance document and fulfills the requirements to achieve the purpose of "Safe food for consumers everywhere" (to deliver safe food to all consumers).

"BRC GLOBAL STADARD FOR FOOD SAFETY ISSUE 6", "SQF CODE 7th EDITION LEVEL 2", etc. including "FSSC 22000-October 2011 lSSUE" are approved as GFSI recognized schemes.

Food Safety Policy

-

1. Basic Principles

As a Crispy tempura bits manufacturing company, we pledge to always operate with a customer-first approach to earn their trust. Our continuing mission is for customer satisfaction through the safest and most reliable products.

-

2. Policy

Our three commitments to quality:

- Commitment 1:

- To take the proper quality measures in order to provide a safe product that our customers can be confident in.

- Commitment 2:

- To constantly take feedback from our customers to provide them with a product that meets their needs.

- Commitment 3:

- To embrace opportunities and change, and to take on challenges with a team of employees full of creativity and ingenuity. We will continue to be flexible and committed.

-

3. Action Targets

① We will set quality targets with customer safety and security at the forefront, and strive to achieve our goals as a united company.

② We will actively strengthen communication with our customers, while constantly focusing on their needs.

③ We will strive for awareness of challenges we face.

④ In order to adapt to changing trends, we shall strive to be mindful of the evolving external business environment.

FSMA Compliant Factory

In the United States, the Food Safety Enhancement Act FSMA was enacted in 2011, and our factory was required to be FSMA compliant on September 18, 2017 when exporting to the United States.

Among the sections of FSMA, section 103 had a particularly large impact on Japan-based food businesses. It involves what is commonly known as PCHF, and includes the requirement for a food safety plan with advance prevention and control of safety hazards.

Nakagawa Nagasaki Plant has over 20 years experience of exporting Crispy tempura bits to the US, and also supports FSMA section 103 and PCHF.

※ We currently have 3 staff members who have completed FDA approved training courses on PCQI required by FSMA and PCHF. They also thoroughly train and educate other personnel.

What is FSMA?

Many food accidents occuring in the United States became a major health burden while being considered highly preventable.

The FSMA (Food Safety Modernization Act) was established by President Obama's signature on January 4, 2011 to improve public health by ensuring safety during the manufacturing of the food supply.

What is PCHF?

The requirements of FSMA section 103 adopts the concept of HACCP as a means of improving the safety of foods and provides hygiene management focusing on HACCP or additional hazard analysis and risk-based preventive management for all FDA registered facilities.

PCHF (Preventive Controls for Human Food) is the continuation of the HARCP (Hazard Analyst Risk Based Preventive Control) that developed HACCP and the inclusion of a Food Safety Plan. Risk-based preventive management is a requirement, such as the establishment of PCQI-qualified personnel for preventive management that appropriately conducts hazard assessments.

What is PCQI?

PCQI (Preventive Controls Qualified-In-Division) is a qualified person who can ensure the implementation of PCHF and review records.

PCQI is equivalent to the standard curriculum that the Food and Drug Administration, the FDA, deems appropriate, and requires qualification through work experience. It properly defines the education and training for the development and appropriateness of risk-based preventive management, and development / application of food safety systems.